By Ryan Goertzen | June 06, 2025 | Ink Jet Printers | 0 Comments

From 1D to 2D: What You Need for Sunrise 2027

Barcodes have been a trusted tool in retail and manufacturing for decades. They’ve helped track products, manage inventory, and keep operations moving. But the way we do business is evolving—and fast. Today’s supply chains demand more: more data, more visibility, and more ways to ensure product safety and authenticity.

That’s why GS1, the global standards organization behind barcode technology, is leading the shift to 2D barcodes. By the end of 2027, businesses will need to be ready to print, scan, and use these next-generation codes. This initiative, known as Sunrise 2027, is a major step forward—and one that every retailer and manufacturer should be preparing for now.

1D vs. 2D Barcodes: What’s the Difference?

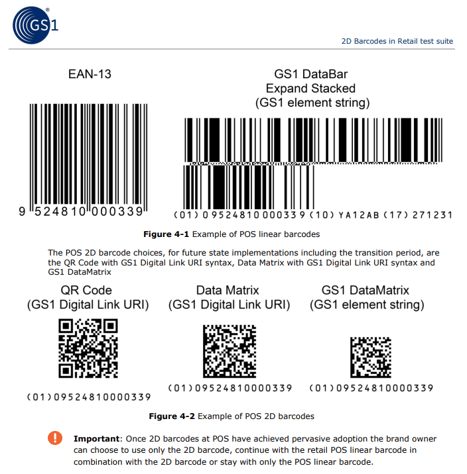

1D barcodes are the traditional black lines you see on most products. They’re simple and reliable, but they only hold a small amount of information—usually just a product number. That means they rely on a database to provide the rest of the details. If the code is damaged or printed poorly, it might not scan at all.

2D barcodes like QR codes, are different. They use patterns—squares, dots, or other shapes—to store more data. They can include:

- Expiration dates

- Batch or lot numbers

- Web links

- Product details

They also scan from any angle and work on curved or uneven surfaces. Even better, they can be read by smartphones and camera-based scanners, not just traditional laser scanners. And because the data is stored directly in the code, 2D barcodes can tell a product’s story without needing to connect to a database.

Why 2D Barcodes Are Better

2D barcodes aren’t just a technical upgrade—they’re a smarter way to manage products in a fast-moving, data-driven world. As GS1 expert Steven Keddie, Senior Director at the GS1 Global office, said, 2D barcodes are a way to connect the physical world to the digital one.

And that connection is exactly what modern supply chains need.

Click here to check out a Q&A article from Steven Keddie all about the transition to 2D Barcodes.

What Sunrise 2027 Means for Your Business

What’s Changing

By the end of 2027, businesses will need to be fully equipped to print, scan, and use 2D barcodes. This includes everything from packaging lines to point-of-sale systems. While 1D barcodes will still be used during the transition, 2D is the clear path forward.

Who It Affects

This shift impacts a wide range of industries—food and beverage, healthcare, retail, logistics, and more. It’s not just a packaging issue; it touches IT, operations, compliance, and customer experience.

Why It Matters

It’s not just about meeting a deadline. It’s about staying competitive, improving traceability, and building a smarter, more connected supply chain. Businesses that start now will be better positioned to lead, not just follow.

Labels vs. Ink: What to Consider for 2D Barcode Printing

As businesses prepare for 2D barcode implementation, one important decision is how those codes will be applied to packaging: using labels or direct-to-packaging inkjet printing.

Labels for 2D Barcodes

Pros:

- Easy to implement: Labels can be printed separately and applied later, which is helpful for small batches or variable data.

- Flexible placement: Ideal for packaging that’s hard to print on directly (e.g., textured, curved, or dark surfaces).

- Low upfront investment: Especially useful for businesses that already use label applicators.

Click here to check out some label applicator systems.

Cons:

- Higher material costs: Labels add consumable costs over time—paper, adhesive, and waste.

- Durability concerns: Labels can peel, wrinkle, or fade, especially in cold, wet, or high-friction environments.

- Slower production: Applying labels can slow down high-speed lines or require additional equipment.

- Environmental impact: More waste from backing liners and non-recyclable materials.

Inkjet Printing for 2D Barcodes (Direct-to-Packaging)

Pros:

-

No extra materials: No labels, adhesives, or liners—just ink on the product or package.

No extra materials: No labels, adhesives, or liners—just ink on the product or package. -

Cleaner, more integrated look: Especially valuable for premium or minimalist packaging designs.

-

High-speed compatibility: Thermal inkjet systems can keep up with fast production lines.

-

Durability: With the right ink and substrate match, prints can resist smudging, moisture, and abrasion.

-

Better for sustainability: Reduces packaging waste and supports eco-friendly initiatives.

Cons:

- Requires investment: Upgrading to high-resolution inkjet printers may involve upfront costs.

- Surface sensitivity: Some materials (like glossy films or certain plastics) may require special inks or pretreatment.

- Maintenance: Inkjet systems need regular cleaning and calibration to maintain print quality.

- Testing is key: Not all inks work on all surfaces—trial runs are essential to avoid unreadable codes.

Expert Tip: For 2D barcodes, print quality is everything. Whether you choose labels or inkjet, make sure your codes are consistently scannable under real-world conditions. Poor contrast, smudging, or misalignment can lead to unreadable codes—and that means delays, rework, or even compliance issues.

Watch Out for These Common Problems

Even with the best intentions, a few common issues can slow your transition to 2D barcodes. The good news is that most of them are easy to avoid with the right setup and a little planning.

One big issue is unscannable barcodes. These usually happen when the print is too light, smudged, or placed in a tricky spot on the packaging. If a scanner can’t read the code, it can cause delays, rework, or even rejected shipments. And when you’re moving at production speed, those small issues can add up fast.

Another common problem is using old printers that can’t handle the details needed for 2D codes. They may struggle with resolution, ink control, or printing on curved or uneven surfaces. That’s where thermal inkjet printers come in—they’re designed to deliver crisp, consistent codes across a wide range of materials and packaging types.

Pro tip: Test your print quality under real production conditions before rolling out 2D codes across your entire product line. What looks good on paper might not hold up on a glossy label or a flexible pouch.

Getting Ready for 2D: A Practical Checklist

Switching to 2D barcodes doesn’t have to be overwhelming. You just need to start preparing for GS1 Sunrise 2027 compliance, which means evaluating your current systems and investing in the right tools for 2D barcode implementation. With the right steps, it becomes a manageable—and even an exciting upgrade to how your business operates.

Here’s a simple checklist to help you get ready:

-

Check your systems

Take a close look at your software, scanners, and data workflows. Can they handle 2D barcodes? If not, now’s the time to explore upgrades or integrations that make sense for your operation. -

Upgrade your printers

Not all printers are built for 2D. Make sure your coding and marking systems can produce high-quality, scannable 2D codes—especially if you’re printing on curved or uneven surfaces. Click here to see some options that could work for you. -

Train your team

Everyone from packaging line operators to IT staff should understand how 2D barcodes work and what’s changing. A little training now can prevent a lot of confusion later. -

Test your setup

Start with a few products or lines. Test how your new codes print, scan, and flow through your systems. This is where you’ll catch and troubleshoot any small issues before they become big ones. -

Work with your partners

Your suppliers, distributors, and retail partners all need to be on the same page. Share your plans, ask about theirs, and make sure your systems can talk to each other when it counts.

Why It’s Worth It

Moving to 2D barcodes isn’t just a box to check—it’s a smart investment in how your business runs, grows, and adapts. Yes, it takes some planning and effort up front. But the payoff is real:

- Stronger tracking across every step of the supply chain

- Fewer errors that slow things down or lead to costly rework

- Safer, more transparent products that build trust

- Happier customers who get the right product, with the right info, every time

It also helps meet upcoming industry standards and prepares your operation for whatever comes next. The businesses that start now won’t just be compliant—they’ll be ahead of the curve.

Get 2D-Ready

Sunrise 2027 is coming fast. Lining things up now means fewer headaches later and sets you up to keep doing what you do best. If 2D barcodes are on your radar, this is a great moment to start turning plans into action.

Need help getting started?

Click here to start a live chat or book a quick meeting with a packaging expert to talk through 2D barcode printing options or any other packaging help you need.

About the Author: Ryan Goertzen

Ryan is the Senior Sales Manager at Rapid Packaging, where he helps businesses improve efficiency and performance through innovative packaging and automation solutions. With industry expertise, he delivers practical strategies that reduce costs, minimize labor, and support sustainable growth. Known for his problem-solving, Ryan consistently drives results that make a measurable impact.

When he’s not helping customers optimize their operations, Ryan’s likely watching the Minnesota sports teams or enjoying the outdoors. From fishing and golfing to grilling and camping, he makes the most of all four seasons across the state he calls home.

Need Help?

Increase your productivity with entry-level of full-line packaging automation, reduce packaging costs, and increase product protection with a full catalog of packaging supplies.