By Pat Flynn | April 18, 2024 0 Comments

Innovative Solutions: Exploring the Benefits of Packaging Automation Systems

In today's dynamic and evolving packaging industry, the role of automation has become increasingly vital in driving efficiency, productivity, and addressing consumer demands. As a business navigating this landscape, understanding the impact and advantages of packaging automation systems is key to staying competitive and meeting market needs effectively. This article delves into the realm of packaging automation, shedding light on its benefits, processes, and impact on the packaging operation.

Unpacking Packaging Automation

At the core of modern packaging operations lies the concept of packaging automation. This innovative approach involves leveraging automated packaging systems to optimize processes, increase throughput along the production line, save time, and cater to the growing emphasis on sustainable packaging solutions within the industry. Companies like Rapid Packaging are at the forefront of providing cutting-edge automation technologies tailored to the unique requirements of businesses.

The Preferred Automation Systems for the Packaging Industry

When considering the preferred automation systems for the packaging industry, the focus is often on fully automated solutions that offer a comprehensive approach to optimizing operational efficiency. These packaging equipment systems integrate cutting-edge technologies such as Palletizers, Case Sealers, and Automatic Strapping Machines to streamline packaging processes effectively. By leveraging these sophisticated automation systems, businesses can achieve significant improvements in productivity, precision, and overall operational performance. There is a wide range of advanced technologies available to optimize various tasks such as:

- Auto baggers are designed for automatic filling and sealing, offering reliability and flexibility in packaging operations.

- Case erectors play a crucial role in automatically setting up cardboard cases for efficient packaging processes.

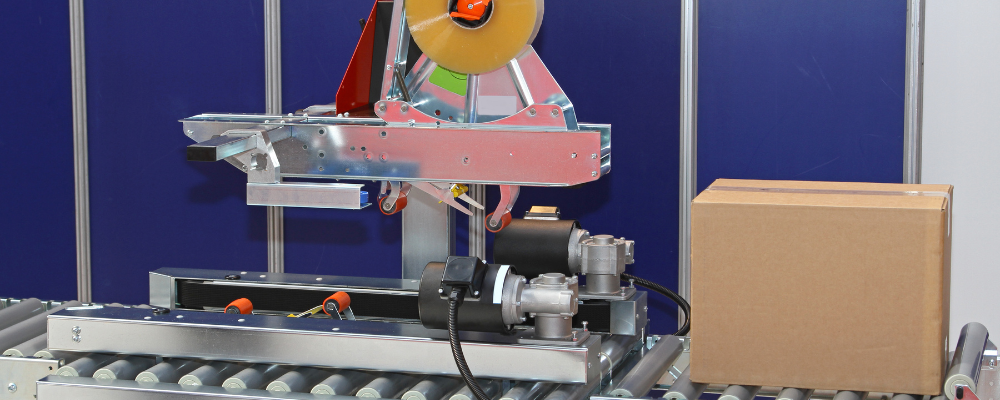

- Case sealers ensure secure closure of cardboard cases, enhancing product protection during transit and storage.

- Conveyors facilitate the movement of products along the production line, optimizing workflow efficiency.

- Palletizers automate the stacking of goods onto pallets, streamlining the loading and unloading processes.

- Shrink wrap machines efficiently wrap products in protective plastic film for secure packaging and transportation.

- Automatic strapping machines provide automated strapping solutions for bundling products together securely.

- Pallet wrappers automate the process of wrapping pallets with stretch film for stability and protection during shipping and storage.

The seamless coordination between various components of fully automated systems ensures smoother workflows, reduced downtime, and enhanced quality control throughout the packaging operation. Moreover, the adaptability and scalability of these technologies enable businesses to meet evolving market demands efficiently and stay ahead of the competition in today's dynamic packaging landscape.

The Benefits of Automated Packaging

- Efficiency Enhancement: By minimizing manual interventions and automating various aspects of the packaging operation, automation systems significantly streamline processes and improve efficiency across packaging lines.

- Speed and Throughput Increase: Automated solutions facilitate faster turnaround times at packing stations, enabling companies to meet consumer demand for swift deliveries while maintaining quality standards.

- Precision and Consistency: Automating tasks like void fill and secondary packaging ensures consistent results, reducing errors and enhancing the overall quality of packaged goods.

-

Cost-Efficiency: While the initial investment in automation systems may be substantial, the long-term benefits, including reduced operational costs and increased productivity, make them a strategic investment for businesses looking to stay competitive.

Decoding the Operation of Packaging Machines

Automated packaging machinery not only enhances operational efficiency but also offers a multitude of benefits such as increased output, reduced labor costs, and improved product consistency. These machines can be programmed to adapt to different packaging formats, ensuring flexibility and versatility in meeting diverse production needs.Additionally, the integration of smart sensors and robotics enables real-time monitoring and adjustments, further optimizing the packaging process. The seamless synchronization of automated packaging machinery with other production equipment results in streamlined workflows, minimized errors, and enhanced overall productivity. This technological synergy fosters a competitive edge for businesses seeking to stay agile and efficient in today's rapidly evolving market landscape.

In conclusion, the transformative impact of automation in packaging extends beyond efficiency gains to encompass enhanced quality control, reduced labor costs, and improved safety standards. Embracing packaging automation unveils a world of innovation, precision, and technological advancements driving the packaging industry forward. By integrating advanced automation systems into their packaging processes, businesses can elevate efficiency, meet consumer expectations for sustainable packaging, and position themselves for long-term success.

Chat now to explore the future of seamless operations with state-of-the-art packaging automation solutions from industry leaders like Rapid Packaging.

About the Author: Pat Flynn

Need Help?

Increase your productivity with entry-level of full-line packaging automation, reduce packaging costs, and increase product protection with a full catalog of packaging supplies.